|

|

| Basic approaches for using silane coupling agents: |

| There are three basic approaches for using silane coupling agents. The silane can be used to treat the surface of the inorganic materials before mixing with the organic resin or it can be added directly to the organic resin or holistic mixing (in organic-inorganic mixture). |

|

The Surface Treatment of Inorganic Materials |

| |

1.1 Glass fiber

Dip glass fiber into 0.1-0.5% silane coupling agent – water solution(or water-ethanol solution) and air-dry, at last dealing in desiccatore with 110-120℃ for 5-10 minutes.

1.2 Inorganic filler

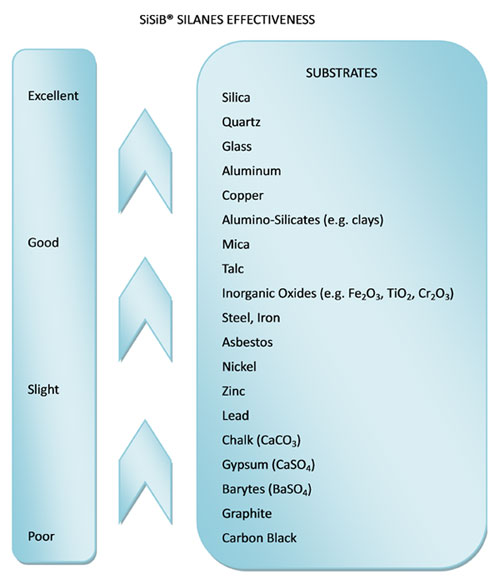

The effect with different kinds of fillers

Fillers: A filler which contains an excess of hydroxyl groups on the surface is especially effective. |

| |

| Much more effect |

Silica, alumina, glass, quartz, porcelain clay |

| Much effect |

Mica, talc, clay, water and alumina, grammiteiron dust, potassium titanic acid |

| Ratherish effect |

Asbestos, ferric oxide, zinc oxide, carborundum, silicon nitride |

| Not very effect |

calcium carbonate, carbon, barium sulphate,boron |

|

| |

There are three general methods for treating the surfaces of inorganic filler materials before they are added to the organic resins.

|

Wet Method |

| |

By mixing a slurry of the inorganic materials in a dilute solution of the silane coupling agent, a highly uniform and precise surface treatment of the inorganic material can be obtained. |

|

Dry Method |

| |

A high shear, high speed, mixer is used to disperse the silane coupling agent into the inorganic materials. The silane is generally applied either neat or as a concentrated solution. When compared to the Wet Method, the Dry Method is most often preferred for large-scale production, treating a large amount of filler in a relatively short time and generating relatively little mixed waste; however, it is more difficult to obtain uniform treatment with this method. |

|

Spray Method |

| |

Spray the silane coupling agent on high temperature filler that was just taken out from furnace. The method may omit dry procedure and make the process simplify, but pay attention to perflation and ignite. |

|

|

Addition To Organic Materials |

| |

Compared to the methods for the surface treatment of inorganic materials, adding the silane to the organic resin is more widely used in industries because of its excellent process efficiency, although curing may be more difficult. There are two general methods. |

| |

|

Integral Blending |

| |

This method involves simple blending of the silane coupling agent into the composite formula as the inorganic and organic materials are mixed together. |

|

Master Batch |

| |

In this method, the silane coupling agent is first added to a small amount of the organic resin material to form what is referred to as a "master batch". In general, the silane coupling agent dosage is 0.2-2% or so. Usually in the form of pellets or large granules, the master batch can be easily added along with the pellets of the organic resin when producing the composite materials. Pay attention to bodying and generate gelatin phenomena by silane coupling agent. |

|

|

Holistic mixing (in Organic-Inorganic mixture) |

| |

Directly add the diluent of silane coupling agent and organic solvent when mixing organic resins and inorganic fillers. The silane coupling agent dosage is 0.2~2% or so.

|

| |

1) CALCULATING THE QUANTITY OF SILANE REQUIRED:

The silicone molecule is preferably attached to the surface of the inorganic material as a primer to form a mono-layer. Applying a silane as a primer will produce optimum coupling results between the substrate and the resin to be applied. When used as a primer the required amount of silane can be calculated by the following: |

| |

|

| |

The actual values may deviate from the calculated value depending on the surface condition of the filler or the silane treating process. The following values may be used as guidelines when the value is unknown. A dilution of 1% silane to filler may be considered as standard. Generally 0.3% to 0.5% is recommended. |

| |

| Surface area of filler |

(m2/g) |

| E-glass |

0.1

- 0.12 |

| Quartz |

1 -

2 |

| Kolin |

7 |

| Clay |

7 |

| Talc |

7 |

| Aluminum

polysilicate |

1 |

| Calcium

carbonate |

5 |

| Calcium

silicate |

2.6 |

|

| |

2) REACTIVITY:

The alkoxy groups of the coupling agents react with water to form silanol groups which immediately form covalent bonds by dehydration and condensation: |

| |

|

| Product Name |

Minimum Coverage Area(m2/g) |

| SiSiB® PC1110 |

436 |

| SiSiB® PC1100 |

353 |

| SiSiB® PC3100 |

330 |

| SiSiB® PC4100 |

314 |

| SiSiB® PC2300 |

398 |

| SiSiB® PC1220 |

380 |

| SiSiB® PC1200 |

351 |

|